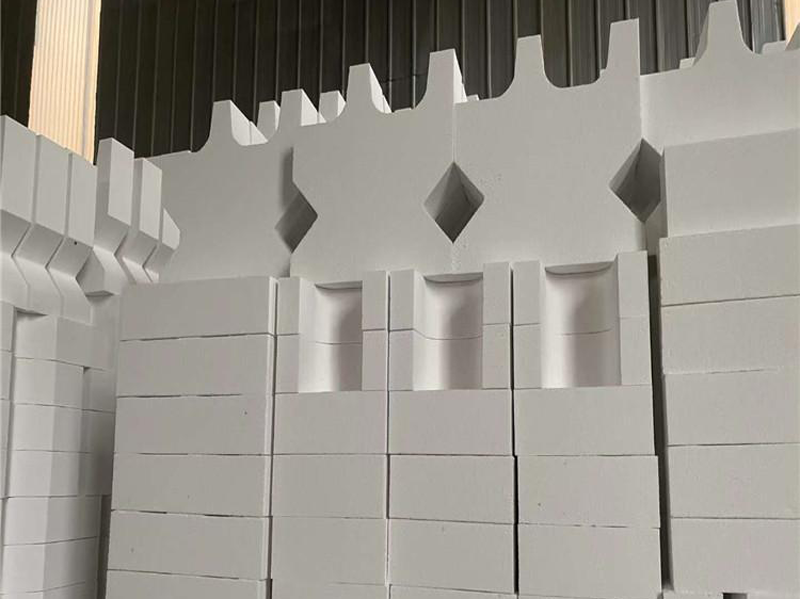

Corundum bricks are a type of refractory brick made from high-purity alumina and have excellent resistance to high temperatures, corrosion, and abrasion. They are widely used in various industries that require a high level of thermal and chemical resistance.

Properties and Advantages of Corundum Bricks

Corundum bricks possess several properties and advantages that make them highly desirable for applications in harsh environments:

High Temperature Resistance

Corundum bricks can withstand extremely high temperatures, making them suitable for use in furnaces, kilns, and other high-temperature industrial processes. They have a high melting point, typically around 2050°C (3722°F), allowing them to maintain their structural integrity even under extreme heat.

Chemical Resistance

Corundum bricks exhibit excellent resistance to chemical attack, particularly from acidic and basic substances. They can withstand the corrosive effects of molten metals, slags, and harsh chemicals, making them ideal for use in industries such as metallurgy, petrochemicals, and chemical processing.

Abrasion Resistance

Due to their high-density and hardness, corundum bricks have exceptional resistance to abrasion and wear. They can withstand the erosive forces of solids, liquids, and gases, making them suitable for applications involving abrasive materials, such as coal gasification plants and incinerators.

Low Thermal Conductivity

Corundum bricks have low thermal conductivity, meaning they are effective insulators. This property helps to minimize heat loss and improve energy efficiency in high-temperature processes. It also ensures better temperature uniformity within furnaces and kilns, resulting in more consistent product quality.

Dimensional Stability

Corundum bricks exhibit excellent dimensional stability even under rapid heating and cooling cycles. They have low thermal expansion, reducing the risk of cracking or spalling during thermal cycling. This property is crucial in industries where temperature fluctuations are frequent, such as glass manufacturing and steelmaking.

Long Service Life

Corundum bricks’ exceptional resistance to high temperatures, chemical attack, and abrasion contributes to their long service life. They require less frequent maintenance and replacement, resulting in cost savings for industries that rely on their durability.

Applications of Corundum Bricks

Corundum bricks find extensive use in a variety of industries and applications, including:

Steel Industry

Corundum bricks are employed in steelmaking processes such as blast furnaces, ladles, and tundishes. They provide excellent thermal and chemical resistance to withstand the harsh conditions of molten metal and slag.

Glass Industry

In the glass industry, corundum bricks are used in glass melting furnaces, tank furnaces, and regenerators. Their high temperature and chemical resistance are crucial for maintaining the integrity of the refractory lining in these applications.

Petrochemical Industry

Corundum bricks are utilized in the petrochemical industry for applications like reformers, pyrolysis furnaces, and ethylene cracking furnaces. Their ability to withstand high temperatures and chemical corrosion makes them suitable for these demanding processes.

Incinerators and Waste-to-Energy Plants

Corundum bricks are used in incinerators and waste-to-energy plants where they resist the corrosive effects of combustion gases and the erosive forces of ash and other waste materials.

Non-Ferrous Metal Industry

Corundum bricks find application in non-ferrous metal industries such as aluminum and copper smelting, where they provide high temperature and chemical resistance to crucibles, furnaces, and other refractory-lined equipment.

In summary, corundum bricks are highly versatile and reliable refractory materials that offer exceptional resistance to high temperatures, chemical attack, and abrasion. Their properties make them indispensable in industries that require durable and heat-resistant materials. Whether it’s in the steel, glass, petrochemical, or waste management industry, corundum bricks provide reliable performance and contribute to the overall efficiency and longevity of industrial processes.