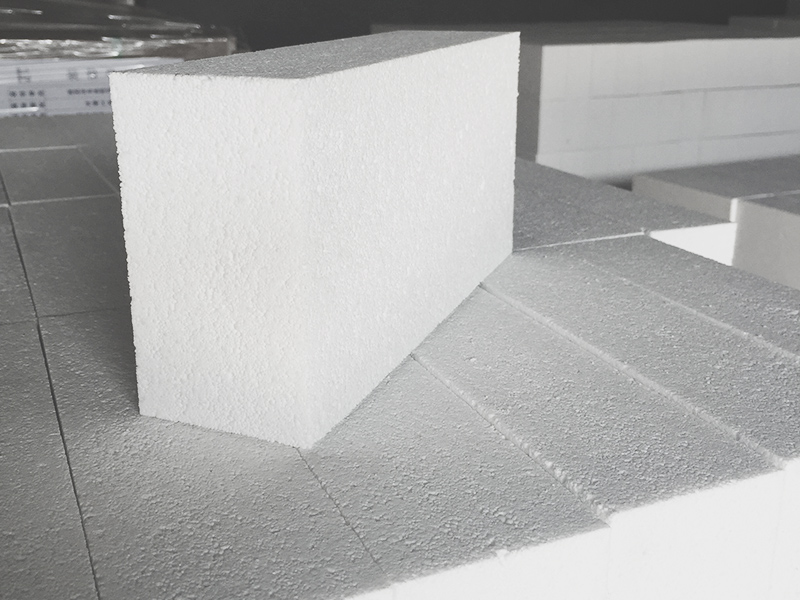

Alumina bubble brick is a specialized type of refractory brick that is known for its excellent insulating properties and high resistance to heat. It is made from high-purity alumina powder or alumina-rich raw materials, which are mixed with a foaming agent to create a lightweight and porous structure.

Properties and Advantages of Alumina Bubble Bricks

Alumina bubble bricks possess several unique properties and advantages that make them highly suitable for specific applications that require superior insulation and resistance to high temperatures:

High Insulating Capability

One of the key characteristics of alumina bubble bricks is their exceptional insulating capability. The numerous closed pores or bubbles within the brick structure contribute to its low thermal conductivity. This property helps to minimize heat transfer, making alumina bubble bricks ideal for applications where heat conservation is crucial.

Lightweight and Low Bulk Density

Alumina bubble bricks have a significantly lower bulk density compared to other refractory bricks. Their lightweight nature allows for easier handling during installation and reduces the overall weight of refractory lining structures. This can be advantageous in reducing the load on supporting structures.

Excellent Thermal Stability

Alumina bubble bricks exhibit excellent thermal stability, enabling them to withstand rapid temperature changes without significant damage. They have a high softening temperature and can maintain their structural integrity even in extreme thermal conditions, such as in high-temperature furnaces and kilns.

Superior Heat Insulation

Due to their low thermal conductivity and high insulating capability, alumina bubble bricks effectively reduce heat loss and improve energy efficiency in various industrial applications. They are commonly used in the construction of hot surfaces, such as furnace linings, kiln linings, and insulation layers, to minimize heat transfer and conserve energy.

Resistance to Chemical Attack

Alumina bubble bricks have good resistance to chemical attack from various corrosive substances, including acids, alkalis, and slags. This property makes them suitable for applications where exposure to harsh chemicals is a concern, such as in chemical processing plants and certain metallurgical processes.

Low Porosity

Alumina bubble bricks have low porosity, which contributes to their excellent thermal insulation and resistance to penetration by gases or liquids. The low porosity helps to prevent the infiltration of molten materials, reducing the risk of spalling or damage to the brick structure in high-temperature environments.

Applications of Alumina Bubble Bricks

Alumina bubble bricks find application in a range of industries and high-temperature processes, including:

Insulation in Furnaces and Kilns

Alumina bubble bricks are commonly used as insulating linings in furnaces, kilns, and other high-temperature equipment. They provide superior heat insulation, reducing heat loss and improving energy efficiency.

Backup Insulation in Refractory Lining Systems

Alumina bubble bricks are often used as a backup insulation layer in refractory lining systems. They are placed behind dense refractory bricks or castables to enhance the overall insulation performance of the lining structure.

Petrochemical Industry

In the petrochemical industry, alumina bubble bricks are utilized in applications such as reformers, ethylene cracking furnaces, and pyrolysis units. Their insulating properties help to maintain high temperatures and improve energy efficiency in these processes.

Non-Ferrous Metal Industry

Alumina bubble bricks find application in non-ferrous metal industries, particularly in aluminum and copper smelting. They are used in crucibles, ladles, and other refractory-lined equipment to provide insulation and protect against thermal shock.

Glass Industry

Alumina bubble bricks are used in glass melting furnaces and regenerators, where their low thermal conductivity and high thermal stability contribute to maintaining stable and efficient glass production processes.

Other High-Temperature Applications

Alumina bubble bricks are also suitable for other high-temperature applications, such as incinerators, waste-to-energy plants, and certain types of heat treatment furnaces.

In summary, alumina bubble bricks offer outstanding insulation, thermal stability, and resistance to chemical attack. Their lightweight nature and low thermal conductivity make them valuable for applications where heat conservation, energy efficiency, and thermal insulation are critical. Whether it’s in the glass, petrochemical, non-ferrous metal, or other high-temperature industries, alumina bubble bricks provide reliable performance and contribute to the overall efficiency and longevity of refractory lining systems.